The advantages of laser cleaning in the thermal power industry are highlighted, and the quality and efficiency are more environmentally friendly.

Laser cleaning, known as the “21st century, the most promising green cleaning technology,” can effectively remove the surface of the object’s rust, oil, film, oxide, paint, and other pollutants without damaging the surface of the substrate.

Application advantages of laser cleaning in tire molds

A mold is an essential tool used in the tire curing process; mold is inevitably in the process of use by the rubber, with the agent and the vulcanization process used in the release agent of the integrated Shen pollution (the primary pollutants are sulfide, inorganic oxides, silicone oil, carbon black, etc.), repeated use will cause some tread pollution dead zone. Therefore, the mold must be cleaned regularly to ensure the cleanliness of its surface to ensure the quality of tires and the life of the mold; given this, the development of tire mold cleaning technology is of great concern to the industry.

“Frontier Exploration” Laser cleaning in the chip industry may be broadcast

Half a month ago, on August 9, 2022, President Biden officially signed the Chip and Science Act. Under the $54.2 billion support for the U.S. semiconductor industry, the bill also clearly states: “Subsidized companies cannot make significant expansions in China and related countries in the semiconductor industry for ten years. At the same time, the U.S. has also formed chip alliances with other semiconductor industry powerhouses, such as South Korea, with frequent moves.

Advantages of laser cleaning over ultrasonic cleaning

Ultrasonic cleaning uses an ultrasonic generator issued by the cross-frequency signal, through which the transducer is converted into a cross-frequency mechanical oscillation and spread to the medium, that is, in the cleaning fluid “bubble” form, the phenomenon of rupture. When the “cavitation” in the object is washed at the moment of surface rupture, resulting in far more than 1000 atmospheric pressure impact, resulting in the object’s surface, holes, gaps in the dirt are dispersed, rupture, and peel off, so that the object of purifying and clean.

How does laser affect the human body?

In recent years, the rapid development of China’s laser industry, the application market is gradually expanding, breaking many problems, unlocking a number of core technologies, and gradually get rid of the dilemma of foreign “neck”. With the vigorous development of the laser industry, more and more people are beginning to pay attention to the development, production and application of lasers. Among them, “What effect will laser have on the human body?” has become a question of great concern. In response to this question, Vico.com will answer for you.

The impact of laser on human body mainly includes the damage to eyes and the damage to skin.

What materials a fiber laser marking machine can mark?

The fiber laser marking machine is the most used laser marking machine. It is not only efficient but also very cheap. So it is loved by many users. However, many people still don’t know much about what materials fiber laser marking machines can mark. So let us introduce to you what materials can be marked by a fiber laser marking machine.

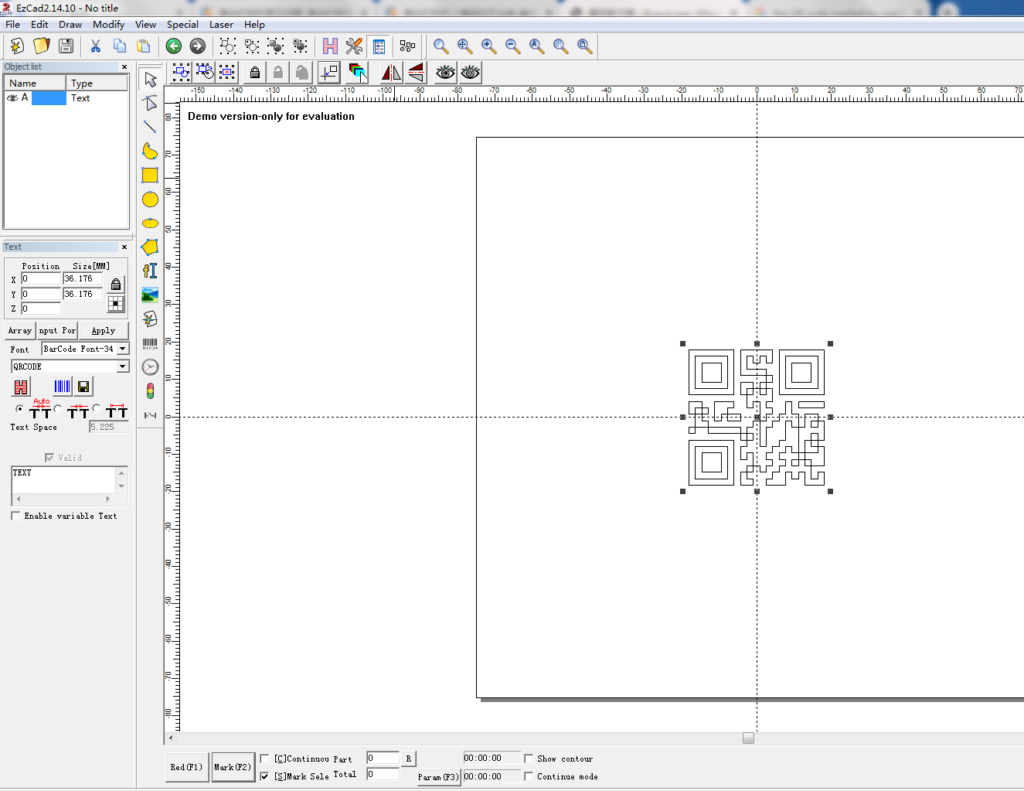

Why can the detector not detect my QR code marked by a laser marking machine?

There are many reasons that the detector cannot scan th […]

How does a Laser Marking Machine or Laser Cleaning Machine Connect with the Production Line?

To begin with this question, we need to know what parts will a production line has.

The conveyor belt is the critical part that all production lines will have.

Besides the conveyor belt, other parts are mainly added to the production process of products. So, all machines or equipment should work with the conveyor belt accordingly.

Laser cleaning is perfect for Lithium Battery manufacturing

As an emerging green “black technology,” laser cleaning has always been one of the research hotspots in industrial manufacturing. However, with the vigorous development of the new energy industry, the demand for lithium batteries has increased sharply. As a result, new tasks and challenges have been proposed for the cleaning process in the manufacture of lithium batteries. In the past two years, under the vigorous promotion of head laser companies, laser cleaning has been applied to the manufacturing process of new energy batteries and has moved from an industrial substitute to a dominant stage.