The market for laser deep engraving

Laser deep engraving is a common laser processing application. Compared with traditional methods, laser deep engraving has no pollution, high precision, flexible engraving content, can meet the complex engraving process, and other advantages; in recent years, the country has paid more and more attention to environmental protection, the traditional corrosion process will also be gradually replaced, laser deep engraving market has a broad prospect.

The effect of pulse width on laser deep engraving

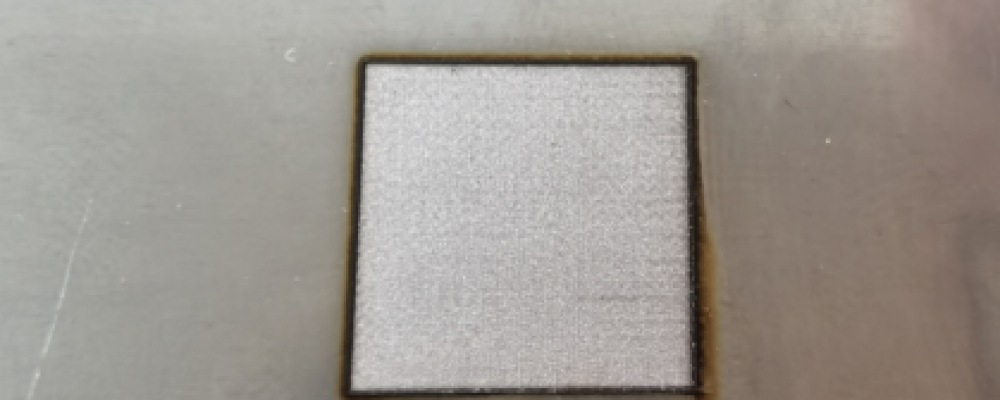

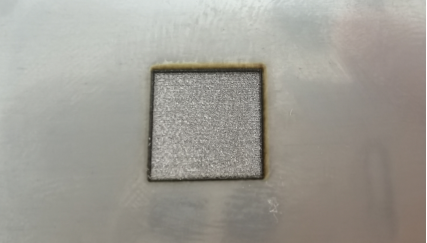

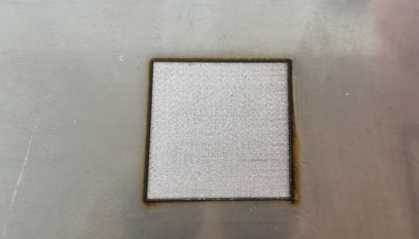

Laser deep engraving is mainly used in mold engraving, wheel engraving, car VIN code, relief artwork, steel logo, gas tank logo, jewelry, and other products, and engraving materials including carbon steel, stainless steel, aluminum, copper, high strength steel, etc. What factors affect these materials’ deep carving depth and the underlying pattern’s roughness? Laser power, beam quality, pulse width, light frequency, filling density, processing speed, etc. This paper focuses on the effect of pulse width on deep engraving.

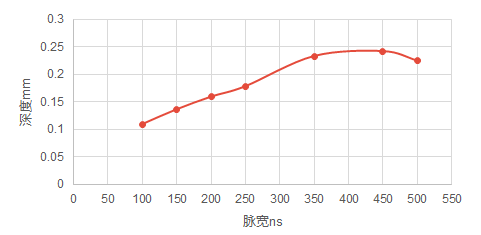

Take stainless steel as an example; test the impact of pulse width on deep engraving; when other parameters are specified, pulse width increases and the depth of deep engraving will also increase; when the pulse width reaches 350ns, the engraving depth is the largest. This is because the pulse width increases to ensure the peak damage to the material damage threshold; the pulse works for a long time to remove high efficiency. Still, the quality of the underlying pattern is not necessarily guaranteed.

The above data analysis concludes that different pulse widths affect the deep engraving effect differently. Therefore, choosing the appropriate parameters to consider the deep engraving efficiency and effect according to the deep engraving demand is necessary.

Bravo Laser Technology launched the MOPA series laser marking machine after unique pulse modulation means, many experimental tests, and parameter optimization, with adjustable pulse width from 1ns to 350ns, in response to the diversification of engraving needs in the market which has significant advantages in deep metal engraving.