On June 9, by China’s high-tech industry portal OFweek Wike, OFweek Wike – laser hosted the laser cleaning online technology seminar successfully held, inviting the industry research and business professionals, focusing on domestic laser cleaning technology trends and applications for technology applications, in-depth explanation, and discussion of laser cleaning solutions and industry layout, on the most cutting-edge laser cleaning technology, industry trends, application cases, solutions and other communication and interaction with attendees.

The following are the excellent reports shared by the participants.

Yao Jianquan, Academician of Chinese Academy of Sciences, Professor of Precision Instrument College of Tianjin University

Talking about the future development direction of laser cleaning from intelligent manufacturing

Academician Yao Jianquan brought a wonderful sharing with the theme of “the development direction of future laser cleaning from intelligent manufacturing.” He firstly introduced that we have entered a new era of intelligent manufacturing with the Internet of Things, big data, artificial intelligence, and other technologies. The manufacturing industry is the foundation of the country and the instrument of the country, and laser manufacturing is one of the leaders and core technologies in intelligent manufacturing.

Laser cleaning has the advantages of safety, environmental protection, precision, low energy consumption, applicability, and mobility; it is a photophysical reaction caused by the interaction between the high-intensity beam, short pulse laser, and pollution layer. On the other hand, the traditional mechanical, chemical, and ultrasonic (wet cleaning) methods are different; they do not require any ozone-depleting CFC organic solvents, have no pollution or noise, and are harmless to humans, and the environment is a “green” cleaning technology.

According to Yao Jianquan academician, foreign laser cleaning to a wide range of decontamination, from thick rust layer to laser surface micro-particles can be removed; the currently developed countries are not new to the application of laser cleaning, has nearly 30 years of experience in use. Currently, the laser cleaning market in Europe and the United States is stable, but due to the limited market space and did not show explosive growth, the real big market in China and some emerging industrial countries. Laser cleaning can be used to clean not only organic pollutants but also inorganic materials. In addition to molds, weapons, equipment, aircraft old paint, metal rust, etc., spray plating process before pretreatment, etc. construction, heritage protection, national defense, household goods, and household and other fields can also be applied to laser cleaning technology.

For the current state of domestic development of laser cleaning, academician Yao Jianquan said there are still some problems: one is used to clean the domestic laser technology, and industrialization is still a lot behind foreign manufacturers; second is the laser cleaning process application point a lot, but did not form a mature system; third is not yet have a guiding test method, instruments, and industry standards.

At present, the team led by academician Yao Jianquan is gathering domestic laser manufacturers, laser cleaning technology research institutes and universities, integrated units and application units, four types of representative organizations, jointly set up an expert committee and industry-standard preparatory group for laser cleaning technology and industry guidance direction.

Ren Yuan, Associate Researcher, Institute of Lasers, Shandong Academy of Sciences

Application Research of Laser Cleaning Tire Mould

Mr. Ren Yuan, the deputy researcher of Shandong Academy of Sciences Laser Research Institute, shared the topic of “Application research of laser cleaning tire molds.”

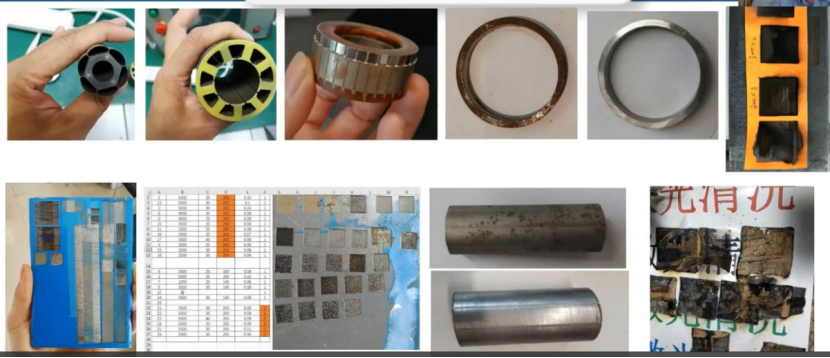

We are not strangers to tires. The ideal state of tire mold cleaning includes online, automatic, no dead angle, no damage, and no temperature reduction. Dr. Ren Yuan introduced, compared with the traditional manual grinding, dry ice cleaning, and shot blasting cleaning methods, laser cleaning can not damage the substrate, extend the service life of the mold, automatic online cleaning equipment, no mold removal, and improves production efficiency.

Laser Institute was founded in 1978; the Laser Institute 2015 set up a laser cleaning team, the laser cleaning core devices, processes, and equipment to carry out research and development, and has set up an exceptional results transformation enterprise – Shandong Industry Research Qiang Yuan Laser Technology Co. Technology level. Through a series of process demonstrations and tire mold laser cleaning optimal path planning, the development of tire mold laser cleaning equipment.

In the field of laser cleaning, Qiyuan Laser has spent six years on research and development and finalized several series of products. Dr. Ren Yuan introduced the products and applications, including solid-state lasers for cleaning, stand-alone machines, mobile cleaning platforms, and laser cleaning solutions. As a result, the company developed a solid laser for cleaning, a laser cleaning stand-alone machine to break the monopoly of sizeable foreign energy solid cleaning laser equipment, the equipment cleaning head quality of 2kg, better than foreign imported equipment, equipment parameters leading domestic, has been in the rail transportation, aerospace, and other fields to carry out demonstration applications; automatic laser cleaning equipment manufacturing for tires, rail transit light industry, the development of mobile cleaning platform, has signed with customers more than Orders, highly recognized by customers; portable laser cleaning machine equipment laser power 100-300W applied to weld cleaning, local dirt removal, precision cleaning high power continuous laser cleaning machine equipment power 1000-2000W efficient removal of metal surface rust and corrosion.

Huazhong University of Science and Technology Professor Wang Chunming

Laser cleaning principle, process, and application analysis

Wang Chunming introduced the history of the development of laser cleaning technology in 1965 by Schawlow, A., L first proposed, Huazhong University of Science and Technology in 2000, the earliest research YAG pulse laser in the aluminum plate paint removal, tire cleaning process, and mechanism of the surface rubber layer. Laser cleaning can be widely used for rust removal, oil removal, paint removal, stripping of coatings (galvanized layer, aluminized layer, protective coating, etc.), removal of alloy (aluminum alloy, titanium alloy, copper alloy) oxide film, pre-treatment before welding and post-welding cleaning.

Wang Chunming gave a specific introduction to the typical application cases of laser cleaning. For example, laser cleaning before brazing the side surrounds of the body-in-white roof, no cleaning before welding, the surface of the weld is prone to porosity defects; laser cleaning of antirust oil before welding of gears, the surface of the workpiece is thoroughly cleaned of oil after laser cleaning, and the original machining knife marks on the surface of the gears are still clearly visible, proving the non-destructive nature of the cleaning. In addition, from the point of view of economic benefits, according to the annual output of 1 million sets of gears, using laser cleaning instead of ultrasonic cleaning can save 1.16 million – 1.96 million yuan.

For the future development trend of laser cleaning technology, Wang Chunming think contains three aspects: one is cross, that is, the process, mechanism, and equipment development direction will cross; second is popularization, laser cleaning is penetrating all walks of life; third is standardization, the urgent need to enhance the volume of the industry, through modularization to change the status quo of non-standardized laser cleaning technology, modularization after the realization of large-scale production, reduce costs, improve cost performance.

Zhang Nan, Ph.D., Nanyang Technological University, Singapore, Technical Director of JPT

Development and Prospect of Fiber Laser in Laser Cleaning

Ms. Zhang Nan, Technical Director of Shenzhen Jepte Optoelectronics Co., Ltd., shared the theme of “Pioneering and Prospects of Fiber Laser Technology in Laser Cleaning” from the perspective of laser light source, introducing the main parameters of single-mode/multimode/multimode combined beam/composite spot laser, the application mechanism and characteristics of different spot modes.

Nan Zhang focused on the introduction of MOPA fiber laser, which is the central oscillation amplification, electrically modulated semiconductor laser as a seed source, amplified by fiber amplifier, characterized by firstly, independent pulse width modulation and repetition frequency; secondly, wide adjustable range of pulse width and wide adjustable range of re-frequency.

In addition, in terms of spot distribution, the spot distribution of the multimode laser is similar to the flat-top spot distribution. Comparing a Gaussian spot and a flat-top spot, the center energy density of a Gaussian beam is high, and the edge energy density is low. The difference between a flat-top beam’s center and edge energy density is negligible. Gaussian spot and homogenized spot have different application scenarios, but if the center energy density of the Gaussian spot is too high, the substrate may be damaged when cleaning. Therefore, the leveling spot can alleviate the substrate damage and improve processing efficiency and effect.

Zhang Nan explained this through specific single-mode laser cleaning, multimode laser cleaning, and compound cleaning cases. Take single-mode laser rail cleaning as an example; the railroad track is composed of high manganese steel, containing a large amount of carbon and manganese elements; its anti-wear, pressure resistance, and hardness are extreme, and the accumulation of rust on the rail erosion leads to uneven rail surface to produce bumps, while affecting the train to receive signals leading to failure, the use of CL single-mode series laser, can reasonably achieve the removal of the rust layer. And the use of CL multimode series laser does not hurt the substrate, has an extended depth of focus, and is better for precision mold cleaning.

In the case of compound cleaning, compound light source cleaning compared to pure pulse cleaning efficiency is faster, pulse laser cleaning in the material heat dissipation is fast, compound cleaning allows the material to maintain a high-temperature state, to assist pulse cleaning effect; but the compound light source cleaning process heat accumulation is relatively large, therefore, cleaning thicker rust, paint layer, the substrate damage requirements are not high, the pursuit of high efficiency can be preferred to compound light source.

Wang Yuntao, Deputy Editor-in-Chief of the Laser Industry of OFweek

Opportunities and challenges in the laser cleaning industry

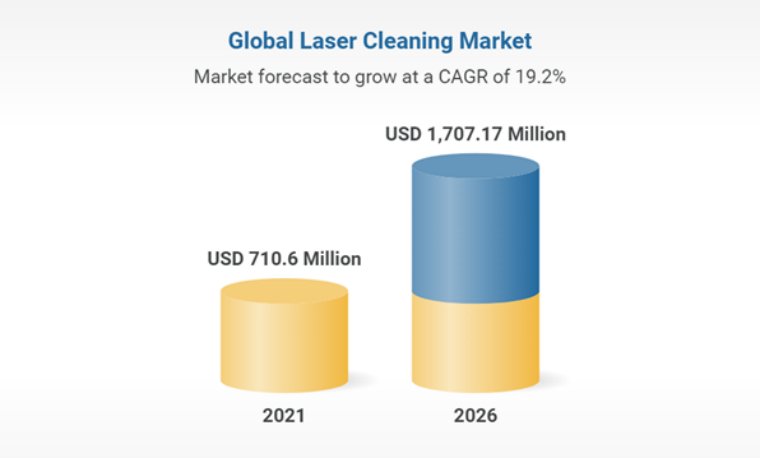

Wang Yuntao, deputy editor-in-chief of the laser industry of OFweek, with the theme of “opportunities and challenges of the laser cleaning industry,” shared three aspects of the development and achievements of the laser cleaning industry, the challenges of laser cleaning, and the development opportunities facing laser cleaning.

Early China’s laser cleaning power is low; the root cause of this bottleneck is the lack of independent research and development of high-power laser light sources. To break this situation, many domestic research institutes and laser companies have invested a lot of money, workforce, core devices, application process research, and development and have made many breakthroughs.

From the application side, laser cleaning advantages are apparent, and the development of the industry has made several achievements. For example, Wuhan Xiangming laser for high-speed rail manufacturing application scenarios for laser cleaning technology to make several improvements in research and development, the application of high-speed rail body welding before and after welding cleaning technology, which is now widely used to clear the welding integrated equipment. Furthermore, in terms of industry standards, in January 2022, QY Laser led the development of two group standards for laser cleaning in the aerospace field, filling the gap in the domestic standard system in this field.

Talking about the problems of laser cleaning, widespread promotion mainly includes three aspects: First, the cleaning parameters need to be repeatedly explored, increasing the cost of downstream applications; Second, the cleaning mechanism is different in various fields, and the degree of standardization is low; Third, the cleaning efficiency has improved, but the cleaning efficiency of complex workpieces is low, in the actual cleaning process, part of the workpiece is irregularly shaped, there are many complex structures and gaps and other not easy to clean to part.

Finally, looking to the future, the laser industry is one of the key directions for the development of high-tech industries in China, the development of laser cleaning technology is also in line with the relevant industrial policies. In terms of policy, due to severe ecological and environmental protection, laser cleaning as a “green” cleaning technology is promising; in terms of technology, the number of patent applications for inventions in the field of laser cleaning is increasing. After entering the 21st century, Jiangsu University, Harbin Institute of Technology, the Chinese Academy of Sciences Institute of Semiconductors, Shandong Academy of Sciences Laser Institute, Grand National Laser, Rui Ke Laser, Water Drop Laser, Qiang Yuan Laser, and a large number of scientific research units and enterprises gradually increase the laser cleaning research, the development and accumulation of laser cleaning technology to contribute to the power, the domestic laser cleaning invention patent application number began to rise gradually. At the same time, laser cleaning technology has entered the “whole life cycle cost feasible” stage to tire mold cleaning; for example, the existing tire mold field is a more environmentally friendly cleaning method for dry ice cleaning compared to the dry ice cleaning method, laser cleaning in the tire mold field has shown economic advantages.