Five industry professionals share with you laser cleaning industry trends, application cases, and market prospects

On June 9, by China’s high-tech industry portal OFweek Wike, OFweek Wike – laser hosted the laser cleaning online technology seminar successfully held, inviting the industry research and business professionals, focusing on domestic laser cleaning technology trends and applications for technology applications, in-depth explanation, and discussion of laser cleaning solutions and industry layout, on the most cutting-edge laser cleaning technology, industry trends, application cases, solutions and other communication and interaction with attendees.

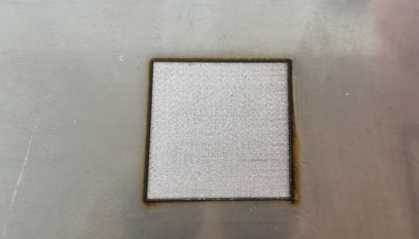

How does deep laser engraving ensure efficiency and results?

Laser deep engraving is a common laser processing application. Compared with traditional methods, laser deep engraving has no pollution, high precision, flexible engraving content, can meet the complex engraving process, and other advantages; in recent years, the country has paid more and more attention to environmental protection, the traditional corrosion process will also be gradually replaced, laser deep engraving market has a broad prospect.

Laserax Canada Announces New LXQ Fiber Laser Marking Machine with Remote Control

Laserax Canada has announced the new LXQ Series fiber laser marker, a marker that redefines ease of use for laser system integration. The laser features are designed to reduce integration time and costs and facilitate collaboration between system integrators and experts – a critical factor in fast and straightforward laser integration.

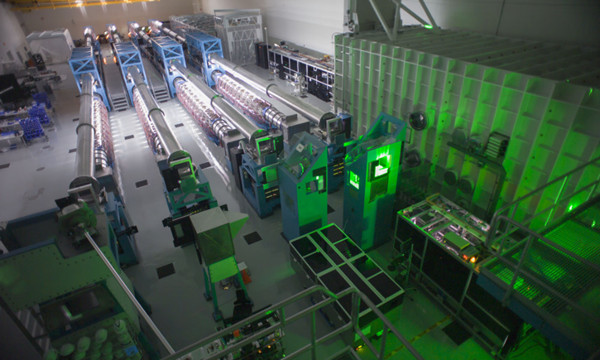

At the cost of $42 million! University of Rochester Laser Energetics Laboratory Begins Major Expansion

The Laser Energetics Laboratory (LLE) at the University of Rochester recently announced a groundbreaking, $42 million expansion of its 66,000-square-foot office and laboratory building in Brighton, N.Y.

What is laser?

Laser is another major invention of humanity in the 20th century after nuclear power, the computer, and semiconductor. The English name Light Amplification by Stimulated Emission of Radiation means “expansion of light by stimulated radiation.” The full name of the laser has fully expressed the primary process of manufacturing the laser. The famous Jewish physicist Albert Einstein discovered the principle of the laser as early as 1916.

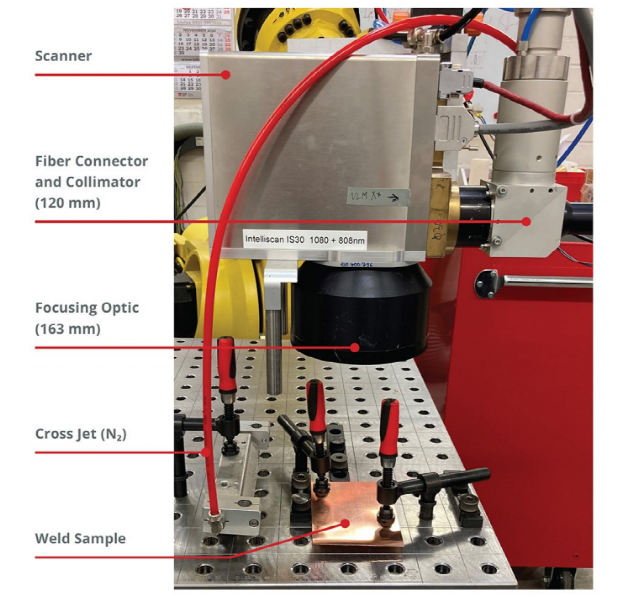

Advanced laser technology for electric vehicles: copper welding with tunable ring-mode fiber laser

This article is originally from Coherent Company. Overv […]

Laser companies are responding to lithium battery technology + manufacturing process advancements.

Laser technology has the characteristics of high efficiency, precision, flexibility, reliability, and stability, low welding material loss, and high automation and safety. It is thoroughly used in lithium battery cutting, cleaning, welding, coding, and other processes. According to the information on the official WeChat account of Laser Manufacturing Network, driven by the strong support of national policies and the acceleration of the promotion and application of new energy vehicles, the demand for automotive power batteries in China has grown significantly. Among the three core components of a new energy vehicle battery, motor, and electronic control, the core component power lithium battery accounts for a high proportion of the cost of the whole vehicle. It also directly determines the cruising range of the whole vehicle.

Why portable fiber laser marking machine is popular in the market?

The laser marking machine industry has also developed rapidly with the rapid development of laser technology. As a result, laser marking technology is popular in all walks of life. With the continuous expansion of market demand, various industries have higher and higher functional requirements for laser marking machines, which forces the continuous development of laser marking machines—faster updates to meet people’s needs.

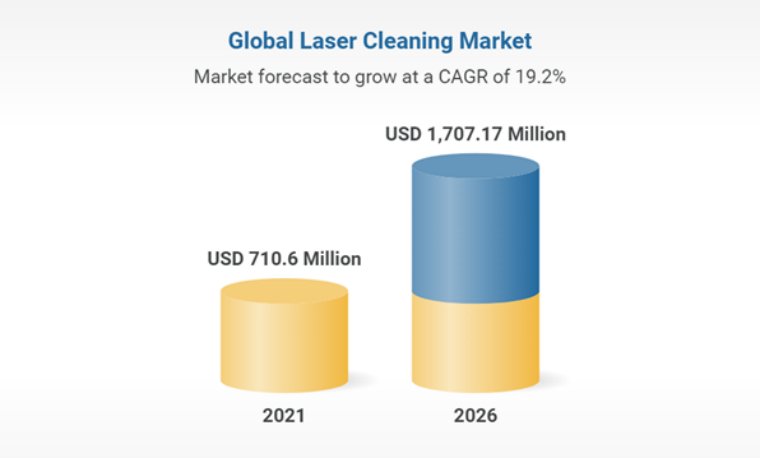

Laser cleaning is perfect for Lithium Battery manufacturing

As an emerging green “black technology,” laser cleaning has always been one of the research hotspots in industrial manufacturing. However, with the vigorous development of the new energy industry, the demand for lithium batteries has increased sharply. As a result, new tasks and challenges have been proposed for the cleaning process in the manufacture of lithium batteries. In the past two years, under the vigorous promotion of head laser companies, laser cleaning has been applied to the manufacturing process of new energy batteries and has moved from an industrial substitute to a dominant stage.