Laser cleaning boosts the “carbon peak, carbon neutral” strategy

The Ministry of Industry and Information Technology issued the end of 2021 the “14th Five-Year Plan” industrial green development plan, indicating the need to build a “green low-carbon technology system, green manufacturing support system.” This initiative has led to new development opportunities for the laser cleaning industry.

Current application fields and future development direction of laser rust removal

aser descaling, also known as laser cleaning, is currently used in abrasive descaling, metal descaling, microelectronics, heritage cleaning, and metal paint removal.

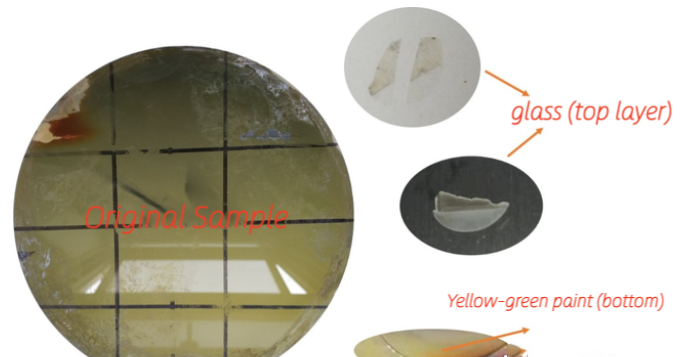

How does a laser cleaning machine remove paint?

Laser cleaners play an essential role in industrial cleanings, such as automobile manufacturing, precision parts processing, building facade cleaning, cultural relic protection, oil removal, and paint removal. So how does laser paint removal work? Laser cleaning machine how to remove paint?

Weld seam laser cleaning machine cleaning without excellent performance

Weld laser cleaning machine to clean the weld surface dirt, after welding the surface will have black dirt, generally uneven surface after welding, most factories with grinding and washing can not be cleaned to the dead ends,

What processes in the tire industry can use laser equipment?

Mold cleaning is generally divided into two cases: mold replacement due to the switch of specification pattern and the other is just mold cleaning rather than the switch of specification pattern. Either one needs to meet two cleaning methods, one is the complete cleaning cycle of mold refurbishment, and one is to extend the complete cleaning cycle of in-line cleaning during production.

Bravo laser helps industrial molds to achieve “green, automatic” cleaning and broadcasting

Molds have a vital role in industrial production. Mold cleaning is the key to maximizing mold life, improving the mold’s reliability, and ensuring product quality. Because the speed of mold manufacturing and development is much faster than the speed of mold cleaning, and the mold, after rapid cleaning immediately to prepare for the next production, so the time left for mold cleaning is quite limited, and choosing an excellent way to clean the mold is more vital because it can not only ensure the quality of subsequent production products, mold maintenance cleaning but also help enterprises to improve efficiency.

Application advantages of laser cleaning in tire molds

A mold is an essential tool used in the tire curing process; mold is inevitably in the process of use by the rubber, with the agent and the vulcanization process used in the release agent of the integrated Shen pollution (the primary pollutants are sulfide, inorganic oxides, silicone oil, carbon black, etc.), repeated use will cause some tread pollution dead zone. Therefore, the mold must be cleaned regularly to ensure the cleanliness of its surface to ensure the quality of tires and the life of the mold; given this, the development of tire mold cleaning technology is of great concern to the industry.

“Frontier Exploration” Laser cleaning in the chip industry may be broadcast

Half a month ago, on August 9, 2022, President Biden officially signed the Chip and Science Act. Under the $54.2 billion support for the U.S. semiconductor industry, the bill also clearly states: “Subsidized companies cannot make significant expansions in China and related countries in the semiconductor industry for ten years. At the same time, the U.S. has also formed chip alliances with other semiconductor industry powerhouses, such as South Korea, with frequent moves.

Bravo Laser: New exploration of new energy pole piece cleaning process

In recent years, the rapid improvement of new energy battery performance has driven the rapid development of the new energy industry. The rapid development of new energy battery applications has put forward higher, newer, and more stringent requirements for battery performance, and battery R&D and production must be continuously improved to adapt to the new market environment.