Laser cleaning boosts the “carbon peak, carbon neutral” strategy

The Ministry of Industry and Information Technology issued the end of 2021 the “14th Five-Year Plan” industrial green development plan, indicating the need to build a “green low-carbon technology system, green manufacturing support system.” This initiative has led to new development opportunities for the laser cleaning industry.

Current application fields and future development direction of laser rust removal

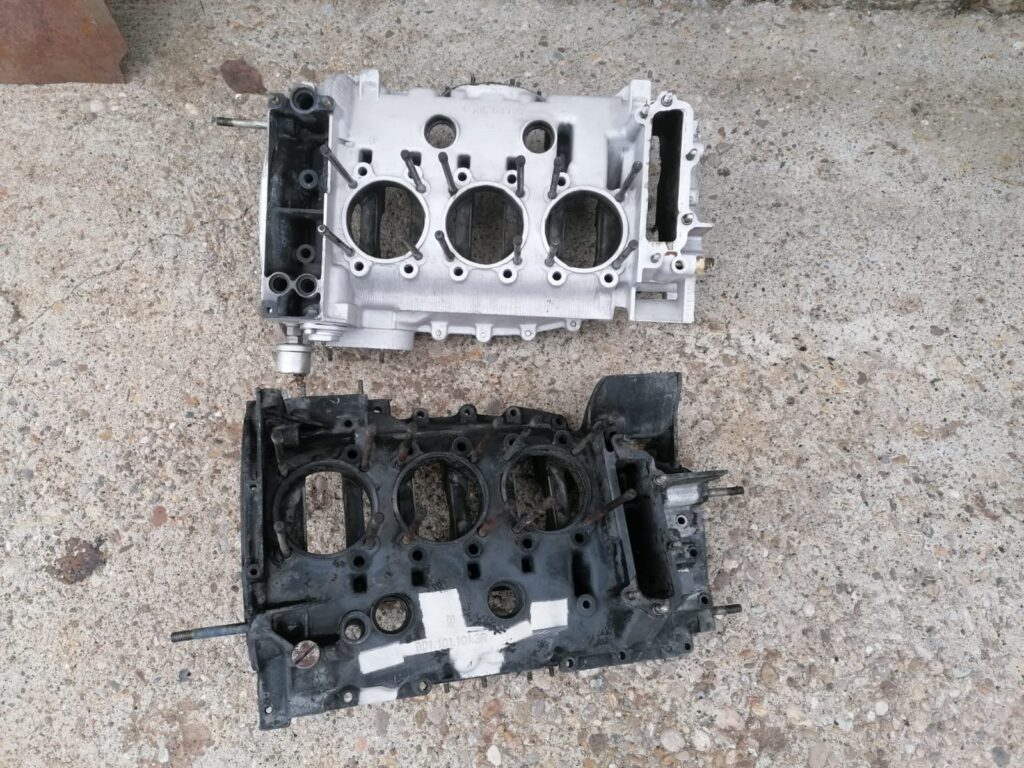

aser descaling, also known as laser cleaning, is currently used in abrasive descaling, metal descaling, microelectronics, heritage cleaning, and metal paint removal.

How does a laser cleaning machine remove paint?

Laser cleaners play an essential role in industrial cleanings, such as automobile manufacturing, precision parts processing, building facade cleaning, cultural relic protection, oil removal, and paint removal. So how does laser paint removal work? Laser cleaning machine how to remove paint?

The advantages of laser cleaning in the thermal power industry are highlighted, and the quality and efficiency are more environmentally friendly.

Laser cleaning, known as the “21st century, the most promising green cleaning technology,” can effectively remove the surface of the object’s rust, oil, film, oxide, paint, and other pollutants without damaging the surface of the substrate.

What processes in the tire industry can use laser equipment?

Mold cleaning is generally divided into two cases: mold replacement due to the switch of specification pattern and the other is just mold cleaning rather than the switch of specification pattern. Either one needs to meet two cleaning methods, one is the complete cleaning cycle of mold refurbishment, and one is to extend the complete cleaning cycle of in-line cleaning during production.