This article is originally from Coherent Company.

Overview

While fiber lasers are the primary laser source for welding, their near-infrared (IR) wavelength output is highly reflected by certain metals, particularly copper, which limits their effective processability for these materials. As a result, high-power solid-state green lasers have emerged as a possible alternative for copper welding, as that metal more readily absorbs these wavelengths. However, these green light lasers have a variety of practical limitations that ultimately lead to higher usage costs.

This paper presents the results of recent copper welding tests successfully performed using a new tunable annular mode (ARM) fiber laser with a high brightness center beam. The high-brightness ARM laser achieved excellent weld quality in these tests and better penetration at various welding speeds than commercially available kilowatt-class green lasers. These results show that this technology can bring the cost, reliability, and practicality benefits of fiber lasers to demanding copper welding tasks.

Electric Vehicle Manufacturing

The booming electric vehicle manufacturing industry is the main factor driving the significant growth in demand for copper soldering solutions. Copper has many desirable electricals, thermal, mechanical, and cost characteristics compared to other metals, which is why it is widely used in electric vehicles (for electric motor stators, batteries, and power distribution systems, i.e., buses, etc.). Moreover, many of these components and systems manufacturers involve copper soldering.

However, while the high electrical and thermal conductivity properties can make copper ideal for these applications, they can also pose challenges for welding using conventional fiber lasers. Specifically, its electronic properties make it highly reflective at the near-infrared wavelengths of fiber lasers. In addition, it has excellent thermal conductivity, so it requires a large input of laser energy to melt the material and begin the welding process.

Therefore, when using conventional fiber lasers, high power is usually required to achieve the power density needed to start melting the material. However, this “brute force” approach can make the welding process unstable and extremely sensitive to small changes in the work surface. In particular, the presence of localized surface oxidation or small-scale surface structural inhomogeneities can lead to an unstable process. Ultimately, inconsistent welds, inferior surface quality, and porosity may be obtained. Also, spattering is prevalent, leading to time-consuming post-treatment procedures or reduced yields.

Solid-state green laser

The green light absorption of copper is nearly an order of magnitude higher than near-infrared light, but only at room temperature. As a result, the energy from a green laser can be coupled more efficiently into the workpiece, resulting in a more stable and less sensitive process than a conventional fiber laser. As a result, some manufacturers are using high-powered solid-state green lasers, while many more are evaluating them.

However, some significant practical issues exist with deploying high-power green light lasers in electric vehicle manufacturing. Some problems stem from these green light lasers’ inherent properties and structure.

Lasers powered by near-infrared light use a frequency doubling function to convert infrared light to green light output, producing a solid-state green fiber laser or a dish laser. While this technology is widely used in low-power (below the kilowatt level) applications, it is beginning to encounter some difficulties at the kilowatt power level required for most industrial copper welding tasks. Specifically, the frequency doubling process itself is only about 50% efficient. As a result, it takes a 4 kW single-mode infrared laser to produce 2 kW of green output power. In addition, the unconverted energy becomes heat and must be removed by a water-cooled heat sink. This makes these lasers energy inefficient (higher power consumption leads to higher operating costs) and requires large amounts of cooling water. In addition, due to the high power used, the frequency doubling crystal will degrade over time, which can create reliability and downtime issues if not monitored at all times. Some designs compensate for this using complex beam shifters and crystal temperature stabilizers.

Another practical problem with green light lasers is that standard optical fibers used for beam delivery are more likely to be dimmed by green light, which shortens their practical lifetime. Specialized fibers for green light can overcome this problem. Still, they are more expensive and less available. The dimming effect also increases with the length of the fiber. Because of this problem, current fiber lengths cannot exceed 10 m, which reduces the flexibility of laser placement in production environments. In addition, the output power of commercially available green high-power continuous wave lasers is currently limited to 2 kW.

Most industrial lasers output near-infrared light, so the entire infrastructure to support them is based on this wavelength. For example, available options for green laser processing heads are limited and often require customization. Similarly, optical components, such as auxiliary lenses, shield glass, etc., are mainly used for infrared lasers. As a result, manufacturers already using infrared lasers may need to keep more spares and consumables in stock to accommodate green laser use in their operations without service delays and downtime.

HighLight™ ARM Fiber Laser

Fiber lasers are much more electrically efficient than solid-state green lasers. As a result, they require less power and generate less waste heat to deliver the rated output power. This reduces the cost of use and simplifies cooling. In addition, fiber lasers are very reliable. Moreover, their infrared light output can be transmitted in real-time through the fiber. However, despite these desirable characteristics, they are not widely used for copper welding because of the problems described earlier.

High-power fiber lasers have been used successfully in automotive production for some time. Still, the most demanding welding technologies on the production line to support electric and lightweight vehicles require more than just elemental energy and high power. While there is quite a diversity of different single applications, most of them typically incorporate.

- Very thin or heat-sensitive materials.

- “Hard” welding materials include aluminum, copper, and high-strength steel.

- Combinations of different materials.

The laser must provide two primary functions to accomplish these more challenging tasks. The first is sufficient energy to support the necessary output rate. High power is also required to achieve sufficient material penetration when working with thicker parts. The second is the ability to precisely control how laser power is distributed over the work surface – in terms of energy density per unit area and per unit time.

Coherent introduced the HighLight family of tunable annular mode (ARM) fiber lasers several years ago and has brought these sources’ cost and practical advantages to applications that cannot be adequately addressed by conventional technology. Typically, the spatial distribution of power and power density on the work surface must be carefully controlled in these tasks to produce good weld quality (reduced spatter, significantly less cracking, and reduced porosity). Typical examples include zero-gap welding of galvanized steel, low spatter welding of powertrain components, and welding of crack-free aluminum suspension components without the use of filler wire.

This precise control of spatial power distribution is achieved by the unique output beam of the ARM laser, which contains a central spot surrounded by another concentric ring beam. The power of the center and annular beams can be independently adjusted and customized as needed, allowing for fine control of melt pool dynamics.

Coherent’s HighLight ARM laser is available in different center/ring beam ratios and power levels up to 10 kW, which can be customized for specific applications. The center diameter can be configured from 22 µm to 100 µm, and the annular beam outer diameter from 140 µm to 200 µm. This is sufficient to perform almost any more critical welding tasks at sufficient output volume. In addition, most of the finest and most demanding conditions typically use less than half the energy.

High intensity, the high-energy-density center beam is required. This provides the energy needed to quickly melt the material for copper welding, even though its absorption coefficient is relatively low. Once the copper is heated, it absorbs infrared light well, and the annular beam heats the material until it melts, followed by a high-powered center beam to build the Keyhole, which maintains some power during the welding process, and stabilizes the Keyhole making it less turbulent and chaotic, substantially reduced spatter. The lower absorption of IR becomes an advantage, and once the Keyhole is established, it becomes easier to penetrate and thus easier to weld thicker substrates. The result is that the weld quality can be consistently maintained from the laser start point, regardless of the surface variation of the part or the amount of thickness difference between the top and bottom material, to create a clean, uniform weld quality with less spatter, thus overcoming the limitations of conventional fiber lasers.

This same ability to develop a heating profile (Temperature profile) based on the material to maximize Keyhole stability and consistency, including at the ends of both sides of the weld, has similar benefits when welding other complex materials such as aluminum galvanized steel. Moreover, it allows high-precision welding of thin, delicate, or heat-sensitive materials.

Copper welding results

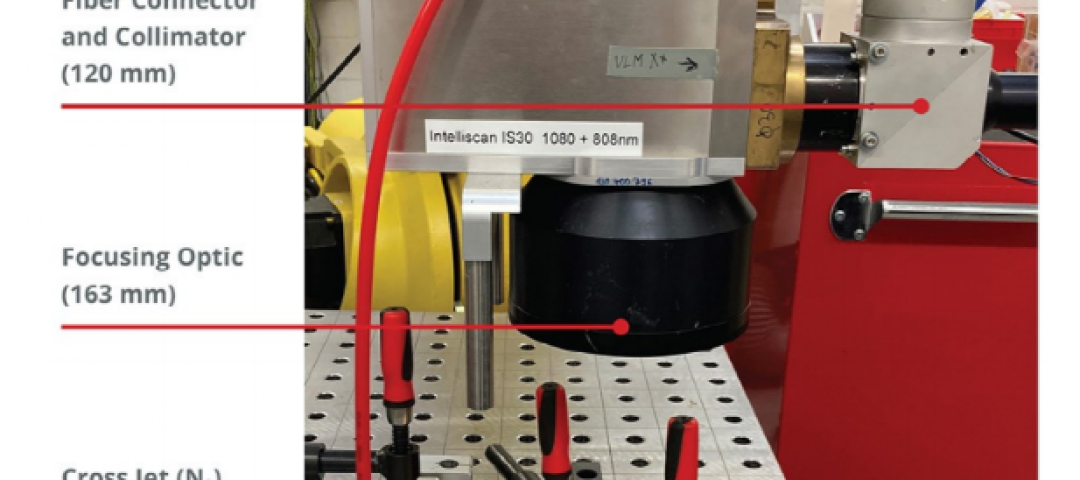

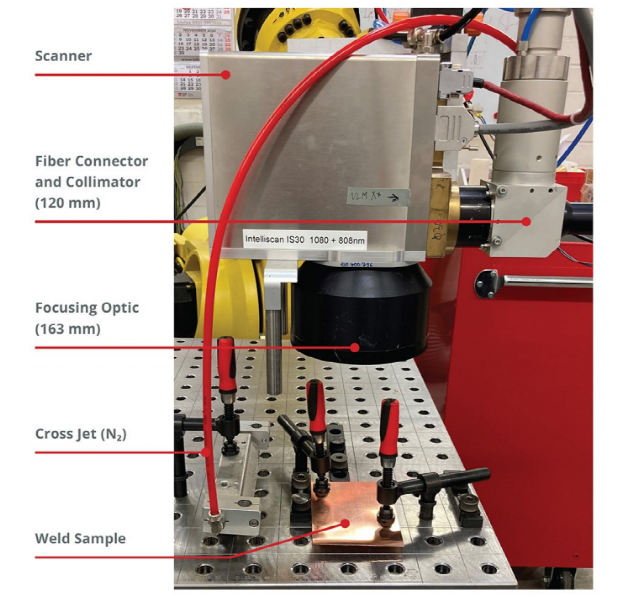

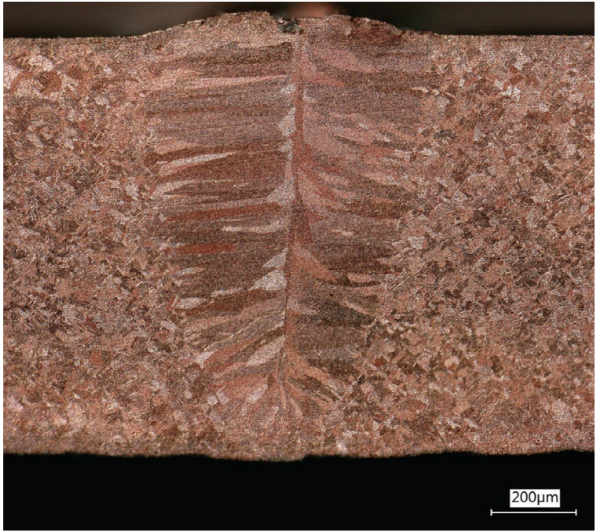

Coherent applications engineers performed a series of copper welding tests using an ARM laser with a high brightness 22 µm diameter center beam and a 100 µm/170 µm ID/OD annular beam. The laser was focused using a distal process head with a magnification of 1.4, and nitrogen was used as the shielding gas and lateral jet. The material welded was pure copper. The laser power was 4 kW for all tests, 1.5 kW at the center, and 2.5 kW for the annular beam. The photograph (Figure 2) shows the experimental setup.

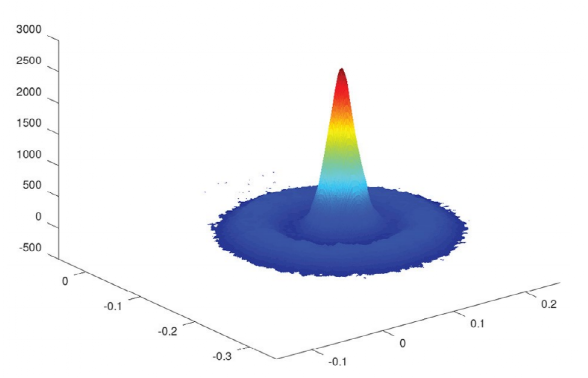

By changing the focal point position, it was finally determined that the best weld quality was achieved when the focal point was set 1.5 mm above the material surface. Specifically, this position is a suitable compromise between weld penetration depth and weld quality. The ARM laser produces a deeper weld penetration depth by focusing directly on the material surface. Still, the resulting weld surface quality and spatter are insufficient for typical electric vehicle applications. Therefore, the figure shows the beam profile on the work surface when using the appropriate beam focus position (1.5 mm above the surface).

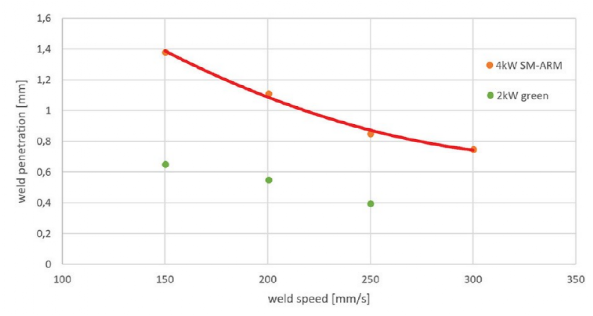

The graph depicts the depth of copper weld penetration versus speed for a thickness of 2 mm under the conditions just described. The 2 kW green laser was also tested under the same conditions. Since the 4 kW, infrared fiber laser produces only 2 kW of green light output; a lower green light power was used. The comparison results show that the IR ARM laser gives twice the penetration depth at different welding speeds.

Welding efficiency

The welding efficiency of the ARM laser was also measured and compared to the previously published welding results of the 2 kW green laser. Nitrogen was used as the shielding gas for both welds. The published data for the green laser showed a (constant) weld cross-section of 0.5 mm² and a penetration depth of approximately 1 mm. The ARM laser was configured to provide these exact results. Specifically, this requires an output power of 3.5 kW and a welding speed of 300 mm/s, compared to 200 mm/s for the 2 kW green laser. Therefore, the welding efficiency of the green laser is slightly higher. However, despite this slight difference in efficiency, the ARM laser provides higher total power and can work at much higher welding speeds.

Surface quality

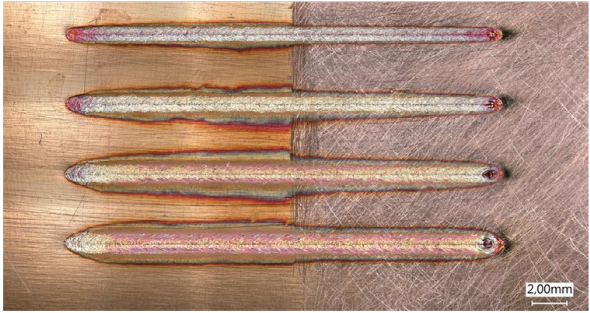

Another essential consideration is surface quality. Conventional fiber lasers are capable of welding copper but are very sensitive to variations in surface quality. The photo shows the weld path of a high brightness ARM laser welding on a sandblasted, polished copper surface. The technique remains stable on both surfaces with no variation in weld quality.

Conclusion

These tests demonstrate that Coherent’s unique high-brightness ARM laser is a practical solution for demanding copper welding applications in electric vehicles. The weld penetration depth and process speed meet or exceed current production requirements. While surface quality sensitivity and process instability issues have previously limited the use of fiber laser copper welding, the ARM laser avoids these issues. The low cost, reliability and practical advantages of this new ARM laser make fiber lasers the preferred choice for many industrial applications and ultimately introduce all these advantages to demanding copper welding tasks.