1. Fully automatic (tire mold) laser cleaning machine

Mold cleaning is generally divided into two cases: mold replacement due to the switch of specification pattern and the other is just mold cleaning rather than the switch of specification pattern. Either one needs to meet two cleaning methods, one is the complete cleaning cycle of mold refurbishment, and one is to extend the complete cleaning cycle of in-line cleaning during production.

1.1 Offline cleaning equipment

An automatic laser cleaning machine is used for regular cleaning treatment of tire semi-steel molds, which can quickly and effectively remove the rubber adhesions, oil, and other stains left in the mold pattern blocks and side plates during production; after cleaning, the mold surface is clean without residual stains, the mold color is uniform without color difference, and the mold surface is free of damage, etc.

After placing the molds on the loading and unloading platform, the laser automation solution can complete the molds’ loading, testing, cleaning, and discharging with just one key start. The time for a complete set of molds to be thoroughly cleaned can be controlled to ≤30 minutes for the pattern block cleaning cycle and ≤5 minutes for the side plate cleaning cycle.

Convenient, simple, and practical, compared with time-consuming wet and expensive dry ice cleaning, have significant advantages. For example, laser cleaning, compared to dry ice cleaning, a tire production plant to clean 1500 pairs of molds a year can save production time 6000 hours; tire production can increase by about 30,000 sets. In addition, the operating cost is negligible; environmental protection and economic benefits are also considerable.

1.2 Online cleaning equipment

Tire curing is the first significant energy consumer in the production process. Generally, tire curing is done by giving superheated water or steam to the mold and capsule at a specific pressure so that the inner and outer temperature of the tire rises above 180°C and about 150°C, respectively, and this process requires a lot of heat. Therefore, according to the current GB29449-2012 national standard process division, the energy consumption of the curing process takes the first place.

The traditional way of mold processing, such as wet cleaning, requires the curing machine to stop for a long time to cool down the mold first and then raise the temperature after cleaning and processing; the whole process is time-consuming and wasteful of heat energy. Meanwhile, the frequent switching of the stove also makes the automatic workshop lose the meaning of saving heat.

Therefore, we are also trying to solve how to realize online cleaning of molds without cooling down during the vulcanization workshop. Based on the original offline cleaning program, the current laser in the 180°C vulcanization workshop can complete the cleaning work, has passed the process test link, and determines the technical program. Therefore, we will strive to complete the fully automated online cleaning machine project.

2. Automatic (inner tire wall) laser cleaning machine

In new energy vehicles, because there is no fuel engine, tire noise and wind noise are more obvious; reducing the noise of tires for new energy vehicles is a concern of all tire manufacturers.

In the production process of high-grade silent tires and self-replacing tires, it is necessary to apply silent cotton or self-replacing adhesive on the inner wall of tires. The tire’s inner wall must be de-glazed and de-separated in the previous process. In this process, it is required not to damage the inner wall surface of the tire and, at the same time to increase the surface adhesion: the inner surface friction coefficient is increased >35mN/m, and the surface tension reaches 38dyne/cm.

The main components of the barrier and glaze layers are methyl hydrosiloxane (5~15%) and water. The water drops laser automatic inner wall cleaning machine can reach 99.99% cleanliness by removing this surface material. The particle size reaches the micron level. Therefore, in the commissioning of the equipment for the customer, the highest technical requirements of 46mN/m or more under a specific process window, the surface tension of 46dyne/cm, more than the customer’s needs, to achieve a higher quality standard. At the same time, the stability of the equipment also reaches the corresponding standard, which can meet the uninterrupted and trouble-free operation of the mechanical workshop.

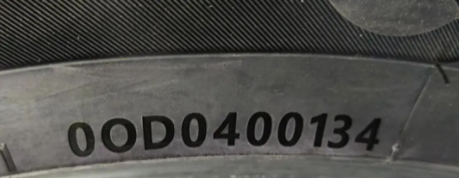

3. Tire marking source system

Laser marking is a mature surface process applied to the finished tire that can be scorched unique logo; once scorched can not be changed, with the advantages of safety, environmental protection, and high anti-counterfeiting. The industry uses more paper QR code labels, but these labels are easy to counterfeit. In addition, the QR code on the tire is easily torn off, which brings uncertainty of warranty.

Water drop laser cleaning machines can consider the use of tire marking without the need for additional equipment; convenient and efficient. After adjusting the process window, the laser marking function, macro engraving of tires, the traceability code in the form of characters or QR code information implantation, and integrated server database can do a crucial query for consumers and manufacturers to facilitate control.

Bravo laser cleaning machine as a new green industrial cleaning process, with micron-level process fineness and unmanned automation of electronic integration advantages, has been widely used in the automotive power battery system, drive shaft, bearings, axles, wheels enough and tires, and other parts of the production process, in the future will further help manufacturing enterprises to reduce costs and increase efficiency, to achieve transformation and upgrading.