What processes in the tire industry can use laser equipment?

Mold cleaning is generally divided into two cases: mold replacement due to the switch of specification pattern and the other is just mold cleaning rather than the switch of specification pattern. Either one needs to meet two cleaning methods, one is the complete cleaning cycle of mold refurbishment, and one is to extend the complete cleaning cycle of in-line cleaning during production.

Bravo laser helps industrial molds to achieve “green, automatic” cleaning and broadcasting

Molds have a vital role in industrial production. Mold cleaning is the key to maximizing mold life, improving the mold’s reliability, and ensuring product quality. Because the speed of mold manufacturing and development is much faster than the speed of mold cleaning, and the mold, after rapid cleaning immediately to prepare for the next production, so the time left for mold cleaning is quite limited, and choosing an excellent way to clean the mold is more vital because it can not only ensure the quality of subsequent production products, mold maintenance cleaning but also help enterprises to improve efficiency.

Application advantages of laser cleaning in tire molds

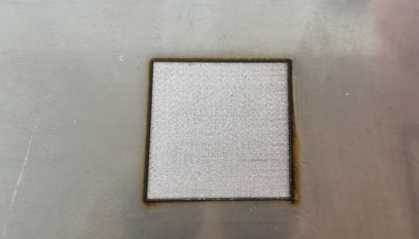

A mold is an essential tool used in the tire curing process; mold is inevitably in the process of use by the rubber, with the agent and the vulcanization process used in the release agent of the integrated Shen pollution (the primary pollutants are sulfide, inorganic oxides, silicone oil, carbon black, etc.), repeated use will cause some tread pollution dead zone. Therefore, the mold must be cleaned regularly to ensure the cleanliness of its surface to ensure the quality of tires and the life of the mold; given this, the development of tire mold cleaning technology is of great concern to the industry.

How does deep laser engraving ensure efficiency and results?

Laser deep engraving is a common laser processing application. Compared with traditional methods, laser deep engraving has no pollution, high precision, flexible engraving content, can meet the complex engraving process, and other advantages; in recent years, the country has paid more and more attention to environmental protection, the traditional corrosion process will also be gradually replaced, laser deep engraving market has a broad prospect.