Laser marking is a versatile and precise method used to create marks, patterns, or designs on the surface of various materials. It operates on the principle of using a highly focused laser beam to interact with the material, resulting in different marking effects without physical contact or tool wear.Unlike traditional methods such as printing or engraving, laser marking offers unparalleled precision and versatility.These advantages make laser marking a preferred choice for industries ranging from automotive and aerospace to electronics and medical devices.

Fiber lasers operate at a wavelength of 1064 nanometers. They are known for their high efficiency and precise beam quality, making them ideal for industrial applications for marking metals and other materials.

UV lasers are crucial in applications that demand precise and high-energy output, such as semiconductor manufacturing, micromachining, biological research, and certain medical treatments.

Carbon dioxide (CO2) lasers are versatile tools widely used in industrial cutting, engraving, and welding of materials like metals, plastics, and wood. Te also utilized in medical surgery and dermatology.

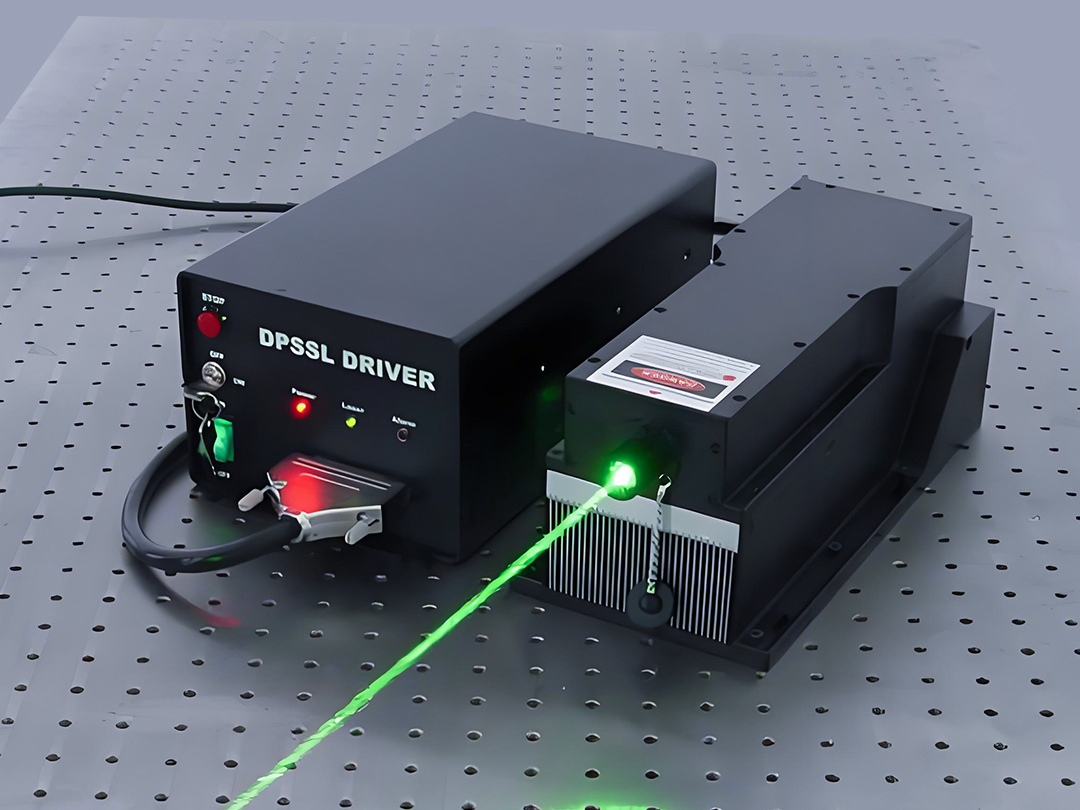

Green lasers are often used in applications such as microscopy, laser light shows, and laser pointers. Green laser light is visible to the human eye and finds use in precision tasks requiring visible light.

| Type | Fiber Laser | CO2 Laser | UV Laser | Green Laser |

| Plastics | √ | √ | √ | √ |

| Leather | √ | √ | √ | √ |

| Wood | × | √ | √ | √ |

| gold | √ | × | √ | √ |

| Silver | √ | × | √ | √ |

| Aluminium | √ | × | √ | √ |

| Iron | √ | × | √ | √ |

| Steel | √ | × | √ | √ |

| Ceramics | √ | √ | √ | √ |

| Rubber | √ | √ | √ | √ |

| Glass | × | × | √ | √ |

| Other Metals | √ | × | √ | √ |

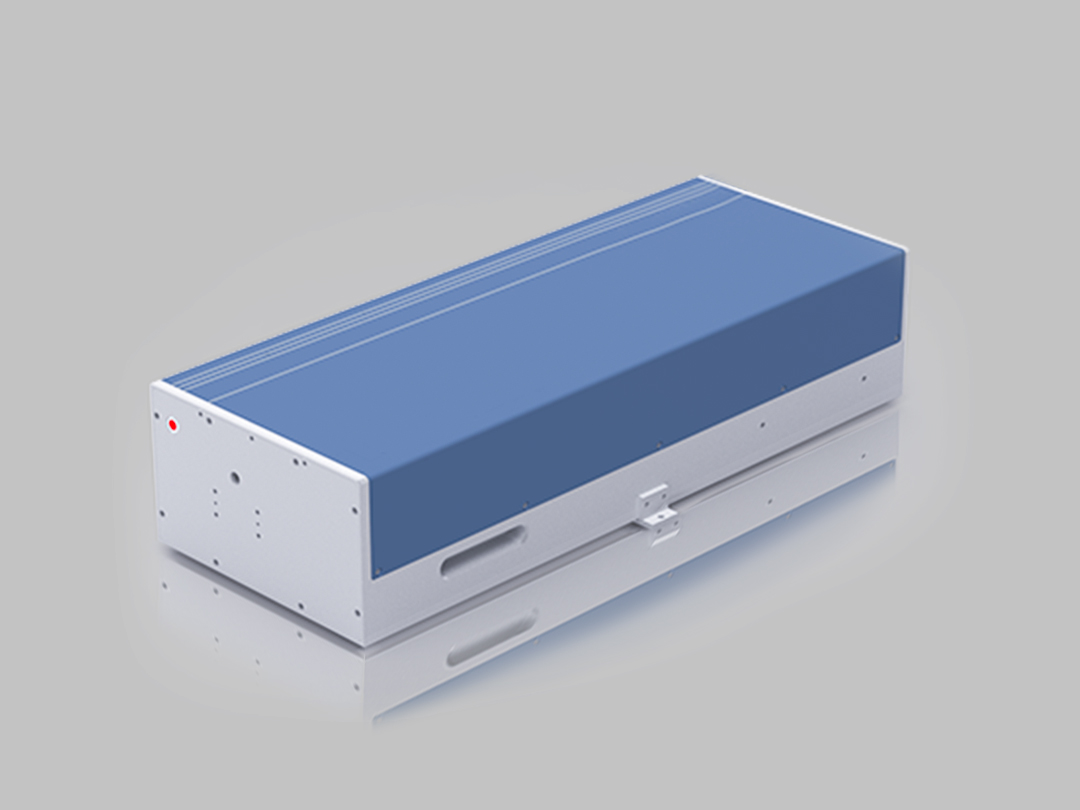

| Laser Power | 20W | ||||||

| Laser Type | Pulsed laser (Fiber) | ||||||

| Weight | 4.5KG | ||||||

| Working Temp | 5℃-45℃ | ||||||

| Cooling Method | Forced air cooling | ||||||

This machine designed for small-scale or localized marking tasks. The emphasis on lightweight design and simple operation suggests it’s versatile and can be used in various work environments. The metal body ensures durability and sturdiness, which are crucial for longevity and reliable performance. If you’re looking for such a device, these features would certainly make it a practical choice.

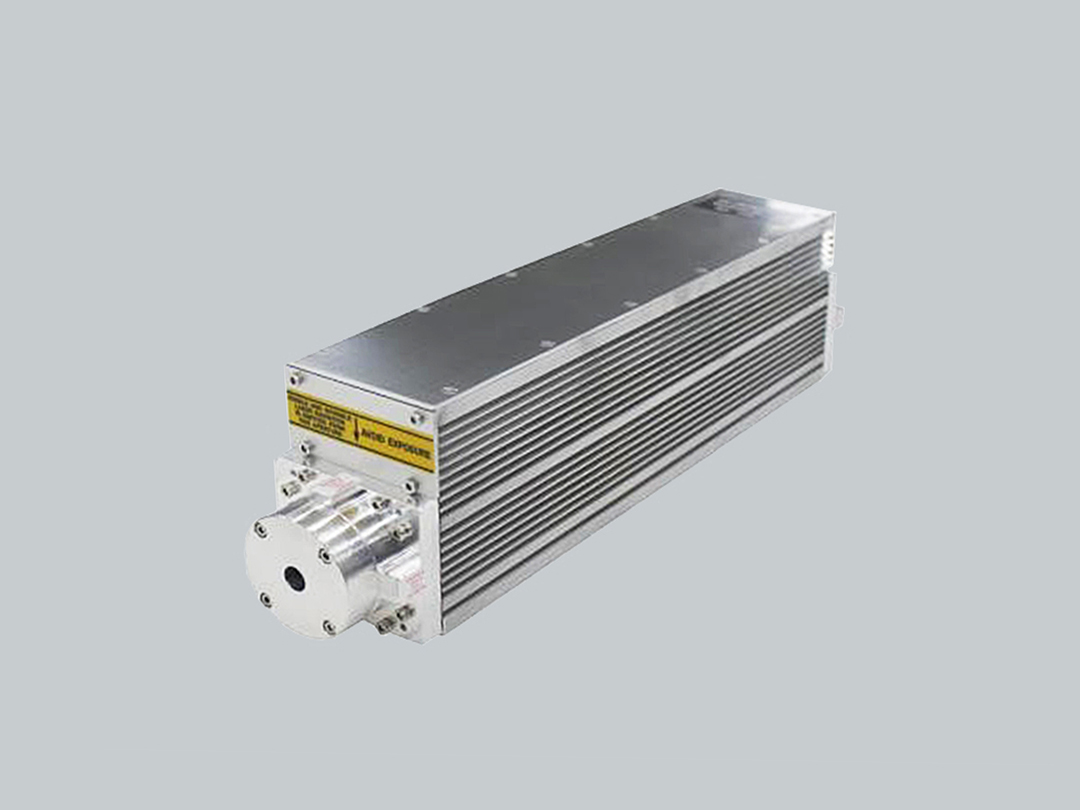

| Laser Power | 20W,30W,50W | ||||||

| Laser Type | Pulsed laser (Fiber) | ||||||

| Weight | 25KG | ||||||

| Working Temp | 5℃-45℃ | ||||||

| Cooling Method | Forced air cooling | ||||||

The device is equipped with a fully enclosed metal chassis and a dedicated laser protective glass cover. This setup ensures maximum safety for operators by containing the laser within a secure enclosure and providing a protective barrier.it offers rich expandable modules, allowing it to be adapted for various marking applications. This versatility makes it suitable for different types of materials and marking requirements.

With over 8 years of dedicated experience in the laser industry, we have accumulated invaluable knowledge and expertise. This deep understanding allows us to anticipate market trends, innovate effectively, and deliver solutions that meet the highest standards of quality and performance.With strong technical support,our products are trusted and utilized across over 60 countries and regions worldwide. This extensive global footprint not only showcases our commitment to quality and reliability but also demonstrates our ability to cater to diverse market requirements. We prioritize customer satisfaction by offering local services in 3 countries. This localized approach enables us to provide prompt support, including maintenance, troubleshooting, and training, directly where our customers operate. It ensures that our solutions are backed by responsive and accessible service.

With over 8 years of dedicated experience in the laser industry, we have accumulated invaluable knowledge and expertise. This deep understanding allows us to anticipate market trends, innovate effectively, and deliver solutions that meet the highest standards of quality and performance.

Our team comprises professional technical engineers and robust R&D teams who excel in developing and supporting a wide range of customized applications. Whether our customers require specific adaptations or entirely new solutions, our technical capabilities ensure that their needs are met efficiently and effectively.

Our products are trusted and utilized across over 60 countries and regions worldwide. This extensive global footprint not only showcases our commitment to quality and reliability but also demonstrates our ability to cater to diverse market requirements. Customers can rely on our products to perform consistently well across different environments and applications.

We prioritize customer satisfaction by offering local services in 3 countries. This localized approach enables us to provide prompt support, including maintenance, troubleshooting, and training, directly where our customers operate. It ensures that our solutions are backed by responsive and accessible service, enhancing overall customer experience and satisfaction.

Collaborating with us is designed to be straightforward and efficient. Here’s how you can get started:

>> Submit Your Requirements: Use the form provided below to send us your specific requirements and contact information. This ensures that we have all the necessary details to begin the collaboration process.

>> Technical Consultation: Once we receive your inquiry, our dedicated technical engineers will promptly reach out to you within 24 hours. They will work closely with you to understand your needs in detail and recommend the most suitable model and pricing options based on your requirements.

>> Contract Signing: After finalizing the model and price that meet your satisfaction, both parties will proceed to sign a contract. This formal agreement ensures clarity and mutual understanding of the terms and conditions of our collaboration.

>> Production and Shipping: Upon receipt of your payment, we will initiate the production process. Our team ensures meticulous attention to detail during manufacturing to meet your specifications. Once completed, we will arrange for prompt shipping to your specified location.

By following these steps, you can expect a seamless collaboration process with us, backed by our commitment to delivering high-quality products and excellent customer service. We look forward to partnering with you and meeting your laser industry needs effectively.